Several FoodTools machines can be equipped with a wire portioning head and if a wire needs replaced follow these simple steps on replacing a cutting wire.

Wire harps are most often used to slice cheese, butter, and other dairy products. In these cases the wire is thin, accurate, durable, and creates less resistance than a blade. If you have questions about using a wire slicing harp for your products, contact a FoodTools portioning expert to discuss the benefits of cutting with wire.

REPLACING A CUTTING WIRE TUTORIAL VIDEO

REPLACING A CUTTING WIRE INSTRUCTIONS

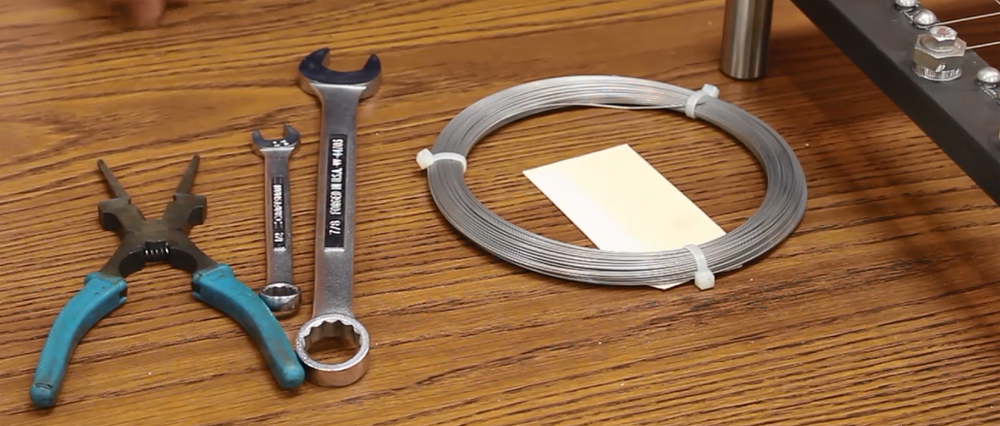

In order to replace a wire on your portioning head you’ll need a spool of wire from FoodTools, a 7/8 wrench, a 1/2 wrench, and needle nose pliers. Always wear safety glasses when working with wire to avoid injury.

Start by removing the old wire from the harp. Both ends are attached to wire nuts and when split the wire can be pulled through each side. Cutting the new wire to the proper length is custom for each wire harp. Consult your cut pattern and to cut the correct length of wire or review the formula included in your owners manual. If you cannot find the correct length for your wire head contact your FoodTools representative and they will assist you.

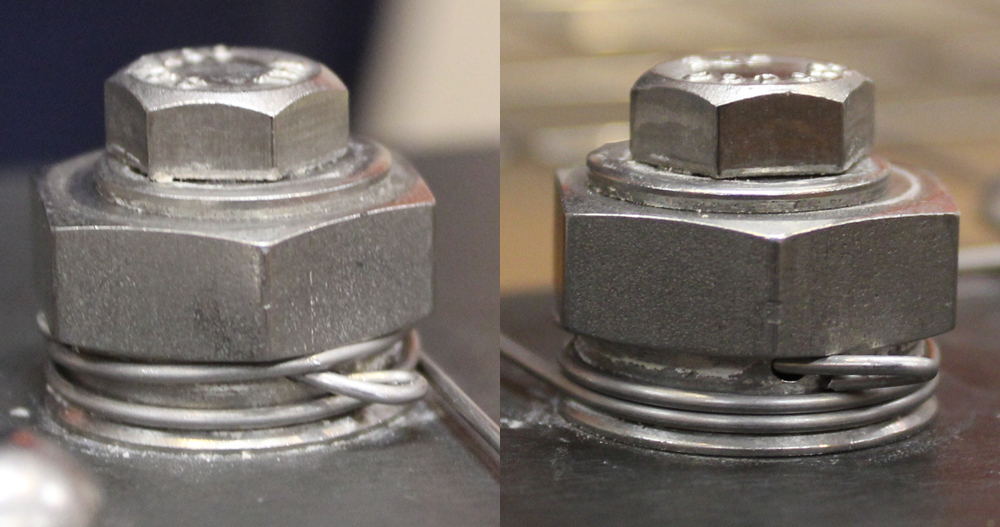

Insert one end of the wire through the hole in the wire tensioning nut and use the needle nose pliers to create a 1/8 inch loop at the end of the wire. Tighten this wire tensioning nut and pull the wire loop flush against it. If your portioning head has rivets you will need to direct the wire around the rivets before reaching the second wire tensioning nut. If your harp does not use rivets pull the available end of the wire toward the other wire tensioning nut.

Insert the other end of the wire through the opposite wire tensioning nut and use the needle nose pliers to create another 1/8 inch loop. Pull the loop flush against the wire tensioning nut and rotate the nut three revolutions to tighten the wire. Be sure to rotate the nut so that the wire is spooled evenly and does not interlace with itself or the wire loop. If the wire crisscrosses the loop or itself unwind it and spool it again evenly.

Use the wrenches to tighten the opposite wire tensioning nut. The tension of the wire itself will depend on the wire gauge and the density of your cutting product.

If you have any questions or need help replacing a cutting wire on your FoodTools hare, consult your FoodTools representative.

DAIRY INDUSTRY RESOURCES

Dairy Foods Magazine | Cheese Market News