At FoodTools we strive to continuously improve user experience and efficiency for all our automated machine offerings. That’s why we are thrilled to introduce our latest innovation: a convenient tooling storage rack system designed specifically for the FoodTools Model 5-AF Series dairy block reduction machines.

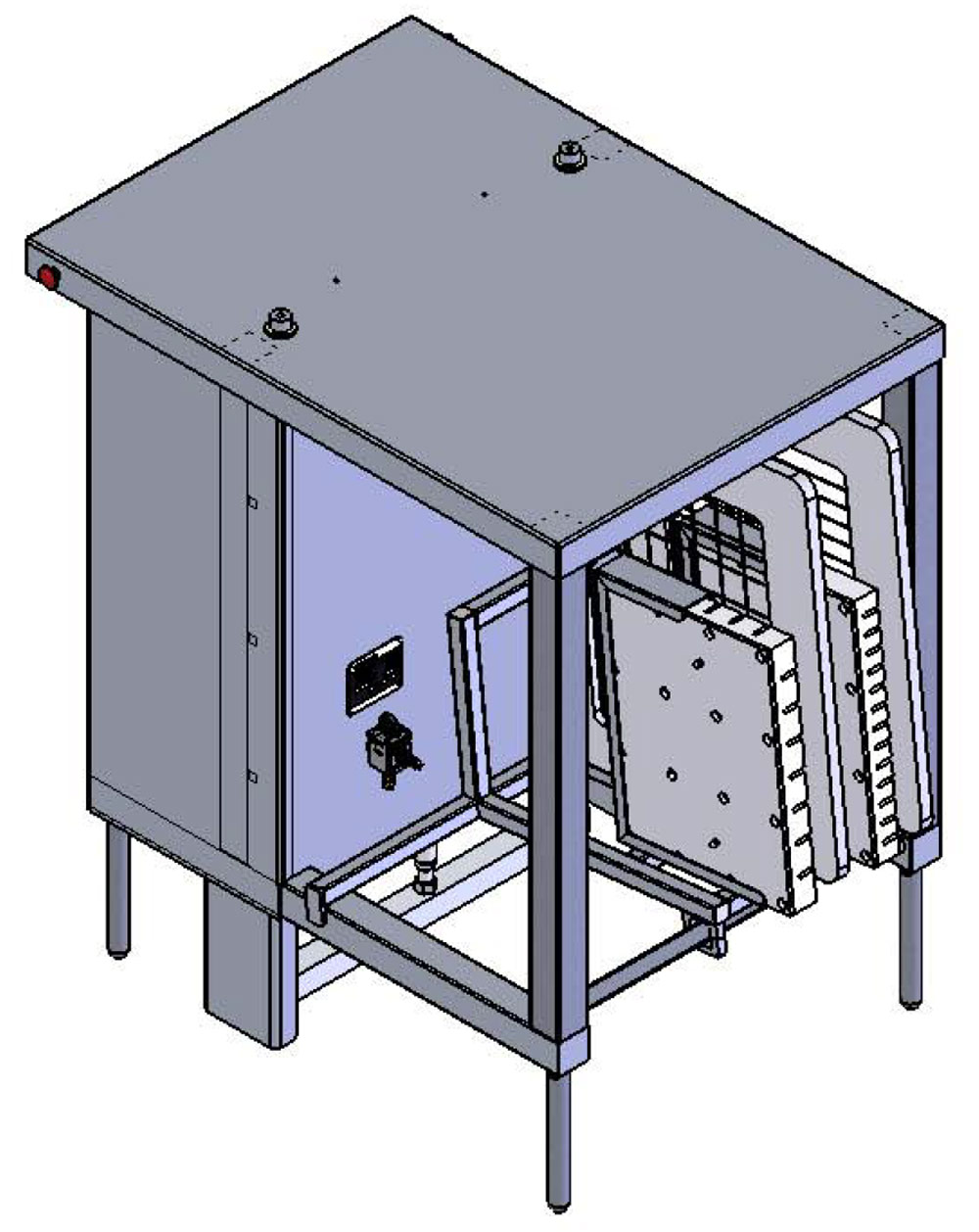

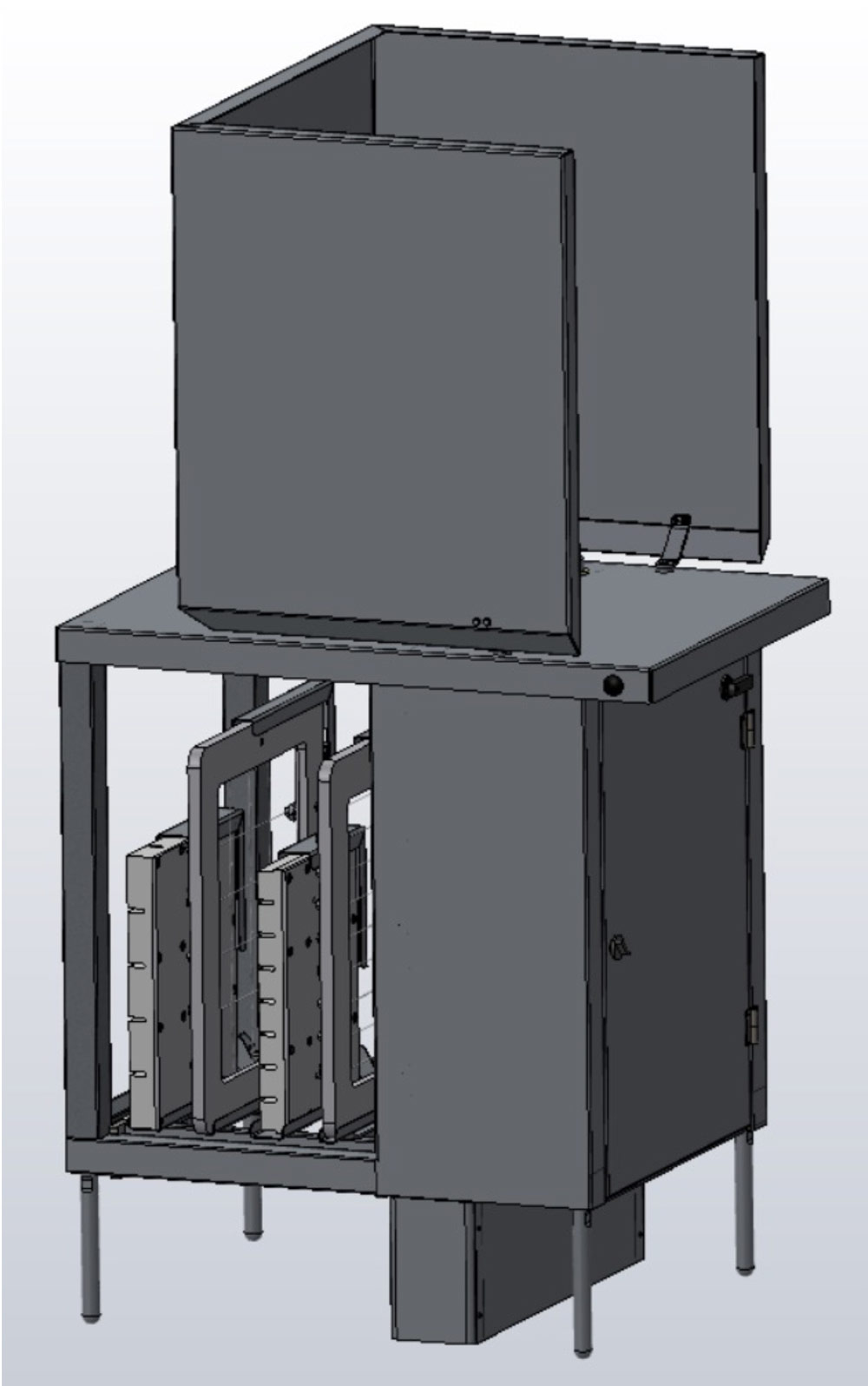

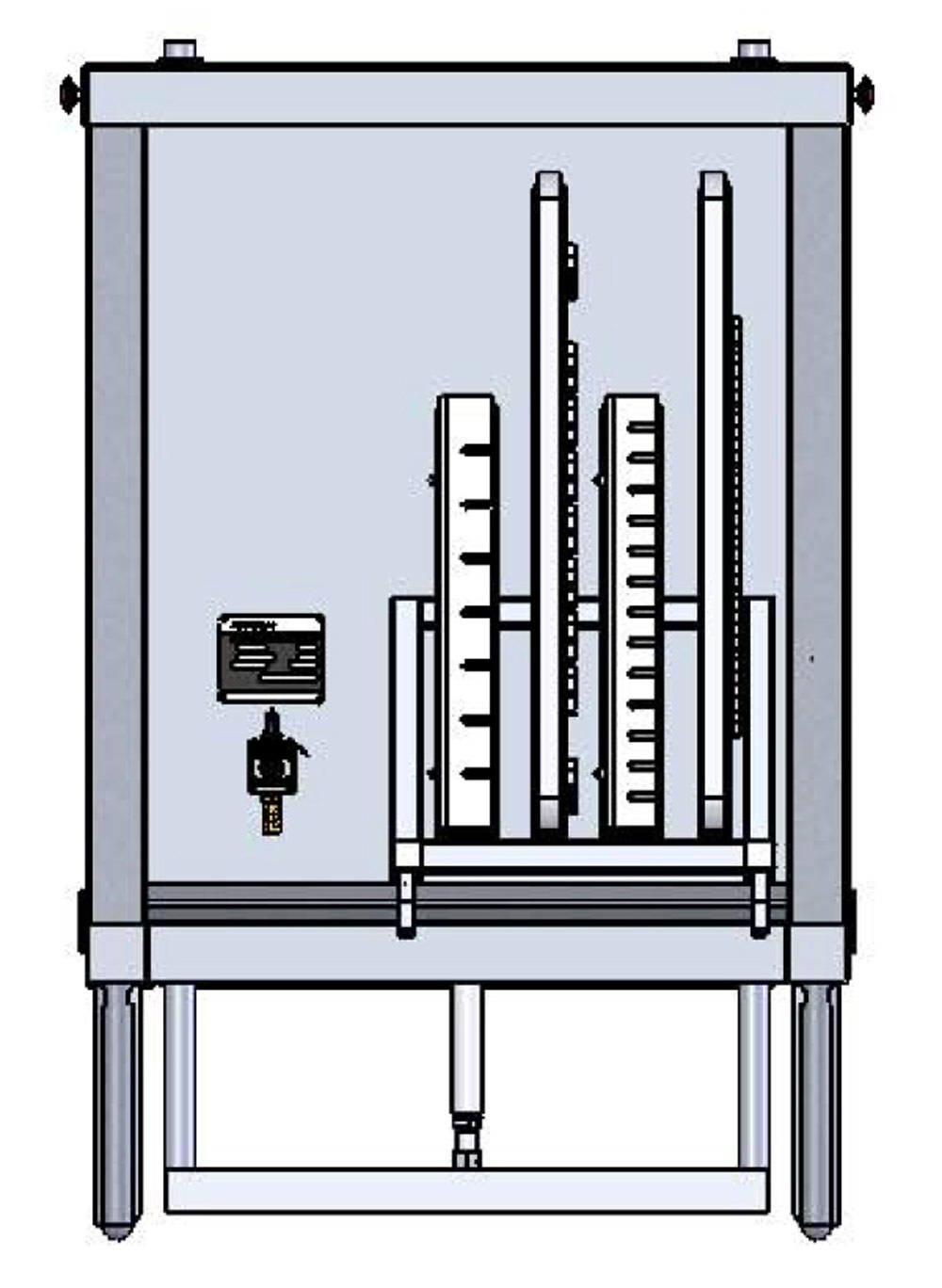

Prompted by feedback from working closely with our customers, this storage solution was created to meet the real needs of 5-AF operators looking for streamlined storage solutions. Storing your change out tooling has never been easier, safer, or more efficient. Our new storage rack system is engineered to fit neatly under the table and at the back of the 5-AF block cutter, optimizing the space in your facility and consolidating all of your harps and bases in one secure place.

Tailored for your unique tooling sets, this storage solution ensures that every cutting harp and base set has its place, preventing damage and lost components. Cleaning and sanitation procedures are also simplified and the workplace is more organized. This storage rack is constructed from high-quality stainless steel and seamlessly integrates onto the machine’s frame, making installation a breeze. The storage rack employs a tilt design to ensure that no standing water accumulates, meeting the most stringent sanitation demands of the food industry.

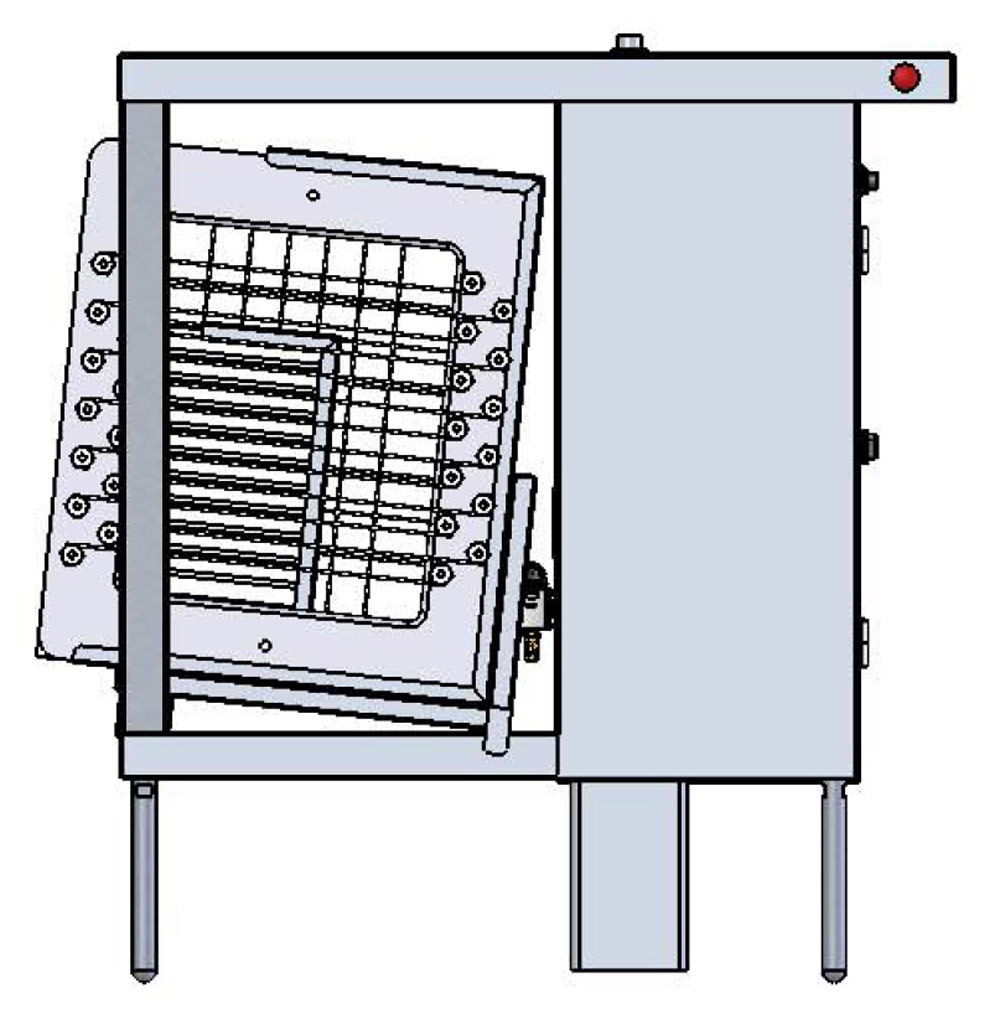

The 5-AF is one of our most popular models of labor-saving equipment. It is an efficient block reduction machine that is designed to safely and quickly reduce blocks of dairy fats like cheese, butter, and shortening to achieve accurate size and weights while eliminating downstream process hazards such as breaking paddles on mixers. This automated block reduction solution uses a wire harp and a matching slotted UHMW base to ensure precise cuts with crisscross grids or laminated slab portions, offering a much safer and faster alternative to manual cutting, increasing employee safety while drastically reducing labor time and expense.

Based on customer data, one operator can reduce up to 300 lbs. (136 kg) of product in approximately 20 minutes, a testament to the machine’s speed, efficiency and reliability. For existing 5-AF owners, this new storage rack is more than just a handy accessory; it’s an enhancement to your daily operations. By keeping your tooling sets organized and within arm’s reach your team can protect its investment, improve workflow, and maintain a cleaner workspace.

Made in the USA with industrial-class materials, the 5-AF is designed following strict safety and hygienic standards. Each unit ships ready to use with custom designed harps and bases and includes a comprehensive operator manual, tool kit, and full documentation. Our team of expert portioning professionals are always available to assist with best practices, preventative maintenance, and unique use cases.

Get ahead of the competition and streamline your block reduction process today. Whether you’re an existing 5-AF owner looking for a superior storage solution or a prospective customer interested in our dairy portioning machinery, we invite you to reach out and schedule a demonstration today. Contact our team of portioning experts to inquire about the new storage rack system and discover why the FoodTools Model 5-AF is the perfect addition to your food processing line.

Additional Dairy Industry Information: International Dairy Foods Association